Table of Contents

A Step-by-Step Guide for New Buyers

For many brands and distributors, the first real engagement with a diaper manufacturer begins with a sampling request. But what actually happens after you click “Request a Sample”? Whether you’re starting a new private label brand or sourcing for retail distribution, understanding the full diaper sampling process helps you save time, avoid misunderstandings, and confidently move forward.

Here’s what to expect—from inquiry to sample delivery, and beyond.

Step 1: You Send an Inquiry with Key Requirements

Once you contact the factory, they’ll collect the basic information needed to create your custom diaper samples:

Size range (NB, S, M, L, XL)

Absorbency level (regular day use or ultra-absorbent overnight)

Packaging preference (branded bag, printed box, bulk pack)

Target market (e.g., USA, Europe, Middle East—this affects compliance standards)

📝 The more detailed your request, the more accurate the sample.

Step 2: Material & Design Customization

Next, the supplier will recommend core materials and help you finalize product specs:

Topsheet softness, backsheet breathability

SAP ratio (absorbent polymer), fluff pulp, and core structure

Elastic waistband, wetness indicator, anti-leak guards

Fragrance vs. fragrance-free, lotion-infused or not

Brand elements: your logo, color scheme, label layout, barcode

If you don’t have packaging design yet, most factories offer design support or standard templates.

Step 3: Sample Production Timeline

Once specifications are confirmed, the manufacturer starts preparing your sample:

Lead time is usually 5–10 working days

Custom film or packaging may take longer if molds are required

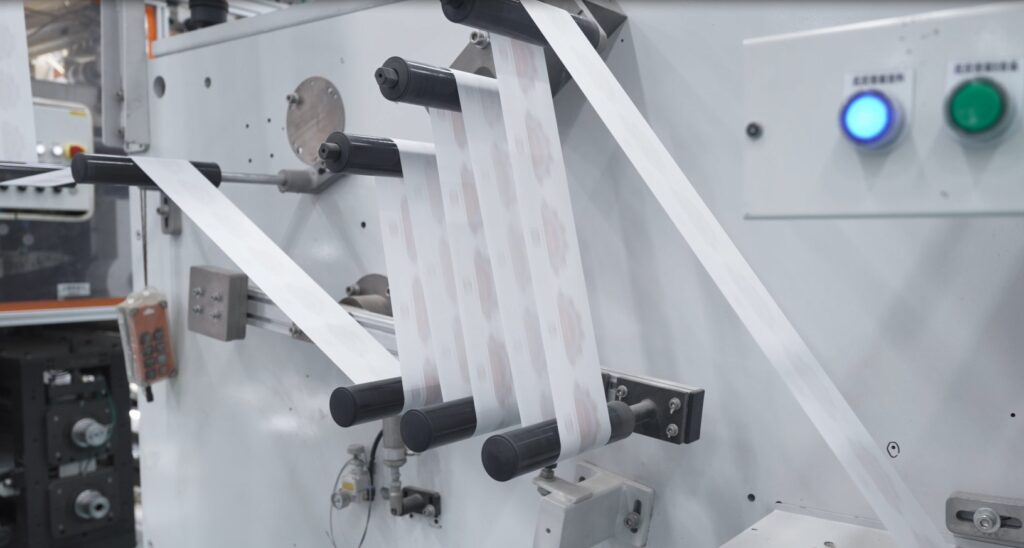

Small-batch machines or hand-assembled units are used for prototyping

You’ll receive clear timelines before the sample is shipped.

Step 4: Sample Delivery & Testing

Samples are typically shipped via DHL, FedEx, or UPS. When you receive the diapers:

Test performance: fit, absorption speed, leakage, odor control

Review packaging: color accuracy, branding alignment

Compare options: if you received A/B samples with different core formulas

💬 Manufacturers appreciate your feedback—it helps tailor your final product.

Step 5: Feedback, Revision, or Order Confirmation

Now it’s time to decide:

✅ You’re happy → proceed to mass production

🔁 You’d like changes → refine the sample (adjust core, improve softness, change artwork)

Most factories allow 1–2 rounds of sample optimization before finalizing.

Final Thoughts: Sampling Is Your First Step Toward a Reliable Diaper Supply Chain

A diaper sampling request isn’t just about testing a product—it’s about evaluating the supplier’s communication, response time, material control, and production capability.

By understanding the process upfront, you’ll not only avoid delays but also build confidence in your partner—and in your product.

Ready to start your own brand? Your first sample may be the beginning of long-term success.

Frequently Asked Questions

Q: Is the sample free?

Generic samples may be free. Custom samples often have a small cost (refundable upon order).

Q: Can I sample both diaper and packaging?

Yes—serious buyers typically test both product and presentation together.

Q: Can I receive multiple variations to test?

Definitely. Many clients receive 2–3 SAP formulas or topsheet types to compare.